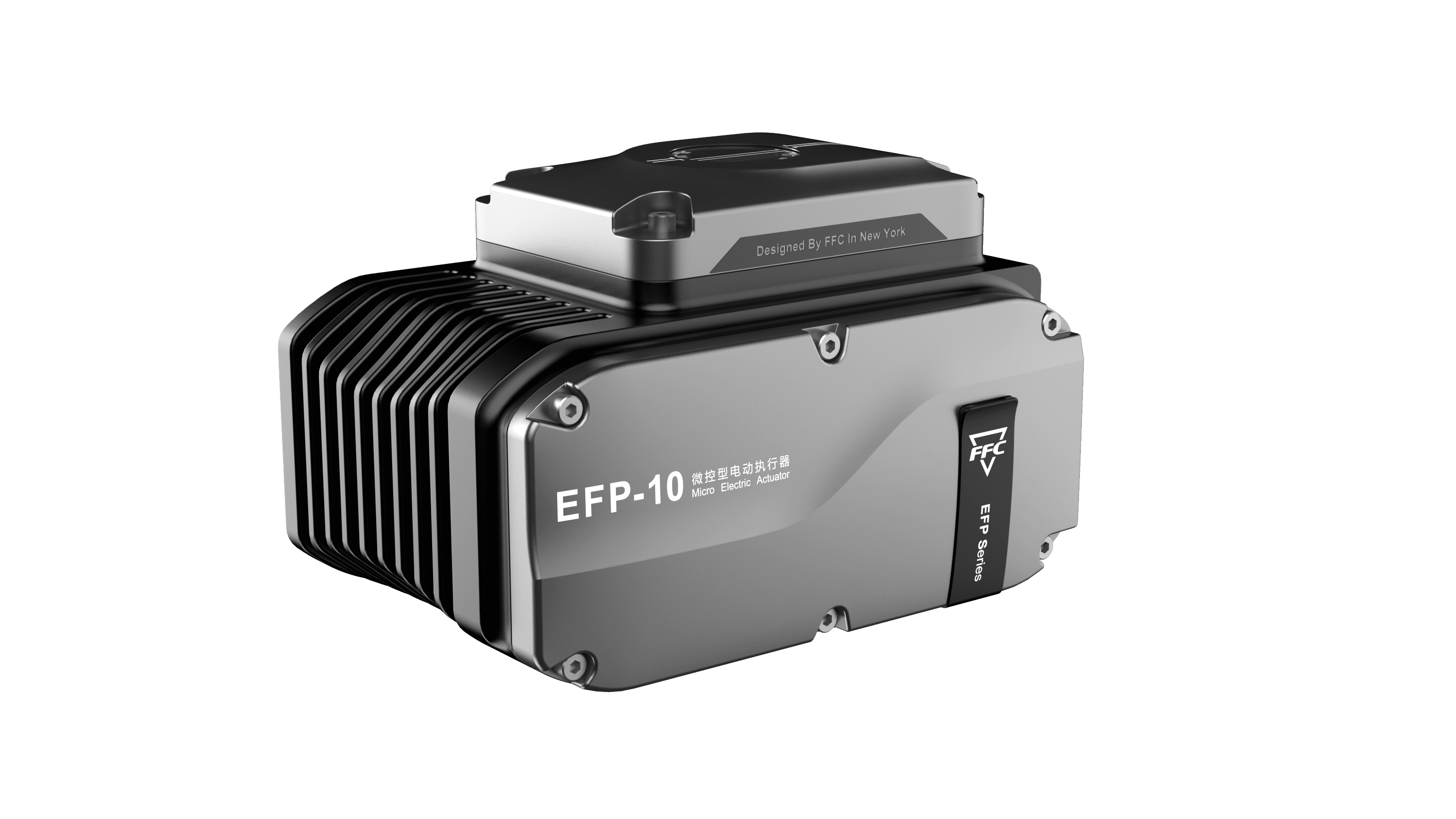

EF-P Series

Feature

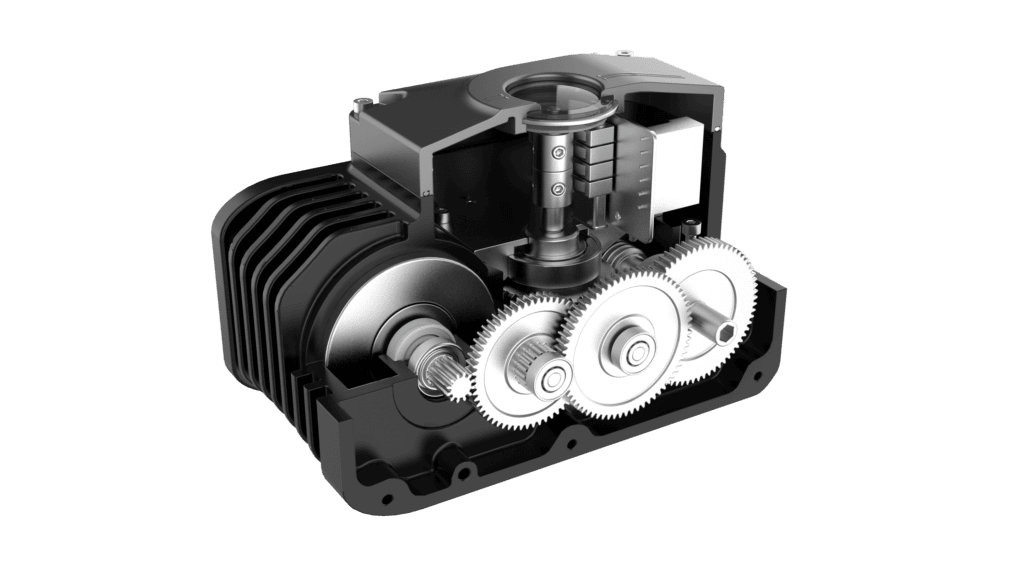

EF-P series micro-control electric actuator is the rotary force of the motor through multi-stage reduction gear, worm gear and other institutions, and ultimately through the output shaft, in the form of rotating 90 ° to switch the valve device, mainly to drive and control the opening of the valve of the angular stroke, such as butterfly valves, ball valves, plug valves, and other similar valves in the application. The output torque range is 50~2500N.m, and the control mode is mainly divided into two categories: switching type and regulating type.

- 100+ Years of Experience

- Personalized move planning

- 24/7 Availability

Specification

| Configuration | Basic | Intelligent Integration | Intelligent | |

| Rotational speed 50Hz | 50Hz | 18、24、36、48、72、96、144(rpm) | ||

| 60Hz | 21、29、43、57、86、115、173(rpm) | |||

| Torque range (direct output) | 50-900Nm | 100-900Nm | ||

| Switching type / Adjustment type | Switching type (external control box required)) | Optional (no external control box required) | ||

| LCD liquid crystal display | Pointer type opening indicator dial | Standard | ||

| No open cover setting | / | Standard | ||

| Infrared remote control | / | Standard | ||

| Field control | / | Standard | ||

| Non-intrusive setting of torque | / | Standard | ||

| Typical Applications | Municipal water supply, water treatment | Water Treatment, Power | Power | |

Request A Free Quote / Product Catalog

You ask, we answer

FFC team is always available for a chat!

FFC is a sub-brand of Material Pioneer Inc, a century-old American industrial group. Focusing on oil, water, gas and other fluid control fields, providing intelligent actuator product solutions, positioning R & D, manufacturing, sales and after-sales service as one of the high-end fluid control technology brand.FFC brand electric actuators from 2020 to start operations, the Chinese operations center (Pioneer Technology (Tianjin) Co., Ltd.) was registered and set up in 2021, all the mechanical components by the parent company’s self-management control, strict quality control of the supply chain, the future will be centered in Germany to supply the European and American markets, to serve the center in Tianjin. Ltd. will be established in 2021, all mechanical parts will be controlled by the parent company, and the quality of supply chain will be strictly controlled, in the future, we will supply European and American market with Germany as the center, and serve Asian region with Tianjin as the center, so as to shorten the delivery cycle and ensure the consistency of product quality.

1, embedded microprocessor control unit can be through the human-computer interface (screen display open, fault information and parameter configuration) using the monitor or remote control to set the stroke and torque.

2、With anti-blocking function, fault self-diagnosis and protection function (self-diagnosis, alarm and protection for abnormal conditions during operation, such as valve jamming, power failure, etc.).

3、Switchable remote and local control.

4、Without open cover debugging function.

5、With local manual and remote control and setting function.

6, with emergency operation function, can set the emergency position.

7、With bus communication function when needed.

8、Intelligent electrical equipment protection level is IP67.

It is made of wear-resistant new material microcrystalline alloy.

In July 1990, the first International Conference on Nanoscience and Technology was held in Baltimore, U.S.A., marking the official birth of nanoscience and technology, which officially declared nanomaterials science as a new branch of materials science.

In 1999, nanotechnology to the market, based on nanotechnology products global annual turnover reached 50 billion U.S. dollars; a number of countries have formulated relevant strategies or plans to invest huge sums of money to seize the strategic high ground of nanotechnology. Japan has set up a nanomaterials research center and included nanotechnology in the research and development focus of the new five-year science and technology basic plan; Germany has set up a special nanotechnology research network; and the United States regards nanotechnology plan as the core of the next industrial revolution.

In 2001, a branch of technology derived from nanotechnology – micro and nano application technology. Some countries’ micro and nano application technology has been applied and achieved amazing results in the field of basic materials, especially many microcrystalline alloy materials made by applying micro and nano technology, which are having a far-reaching impact on human beings and have completely changed people’s way of thinking.

Microcrystalline alloy is a kind of alloy grain refinement to the micron level alloy materials, with this ultra-micro grain alloy can be realized in a special aspect of the performance of extremely excellent comprehensive mechanical properties, super size stability and wear resistance.

The series of friction reducing products made of microcrystalline alloy, such as axle shims, axle bushings, worm gears, slide plates, and filaments, have been successfully applied in the forging and pressing equipment manufacturing industry, numerical control machine tool manufacturing industry, speed reducer manufacturing industry, heavy mining equipment manufacturing industry, and engineering machinery manufacturing industry.

Microcrystalline alloy products have successfully replaced traditional friction-reducing alloys and new friction-reducing alloys with their high reliability and stability, and have achieved good social benefits and great economic benefits.

FFC electric actuator has applied the material of microcrystalline alloy in the production of worm gear and slide bearing, and made the product test according to the industry standard. Fully meet the use of products, and product costs have been effectively reduced.

Get a free quote now!

Super simple, tell us the required size, quantity and we will quote within a day