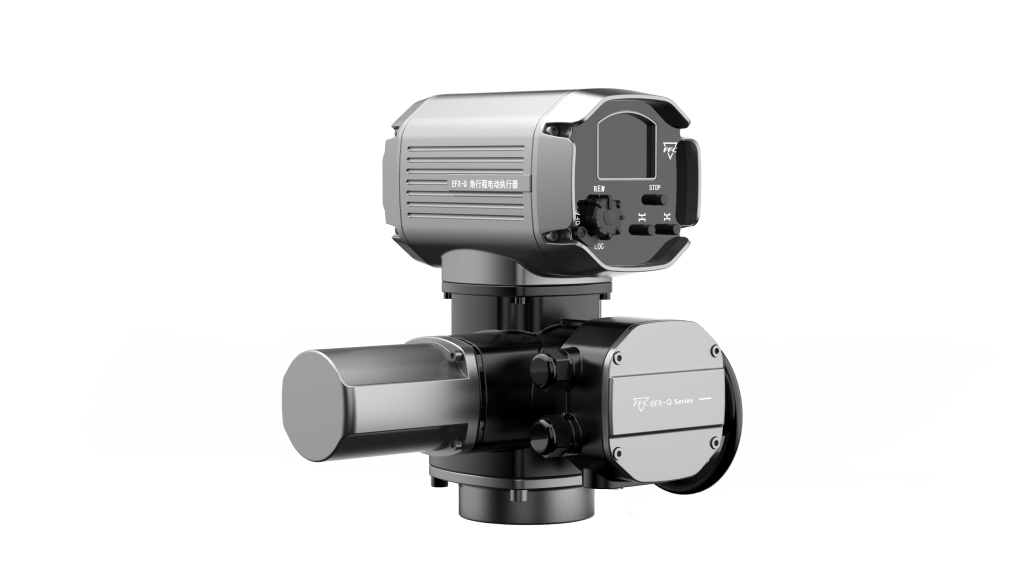

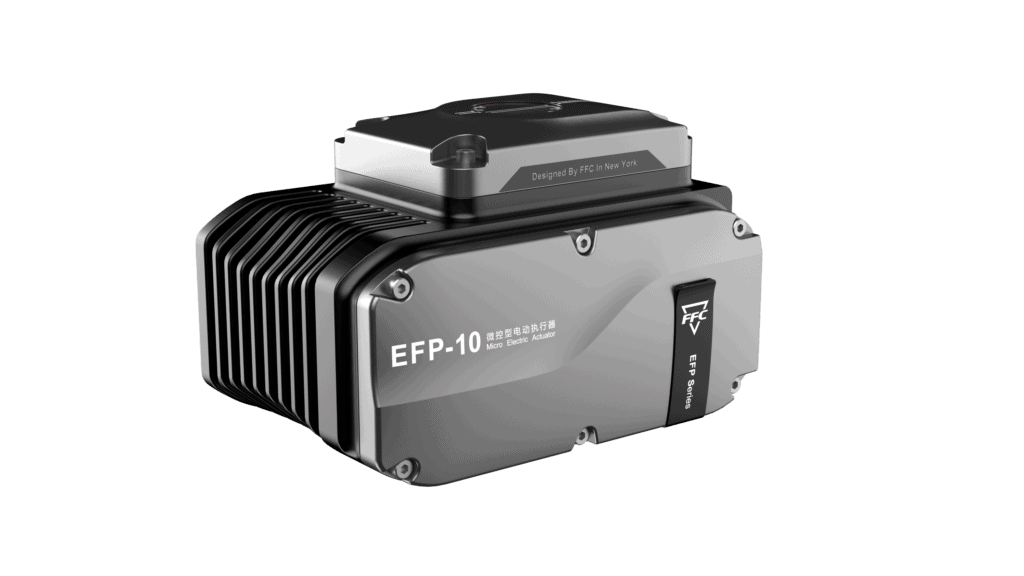

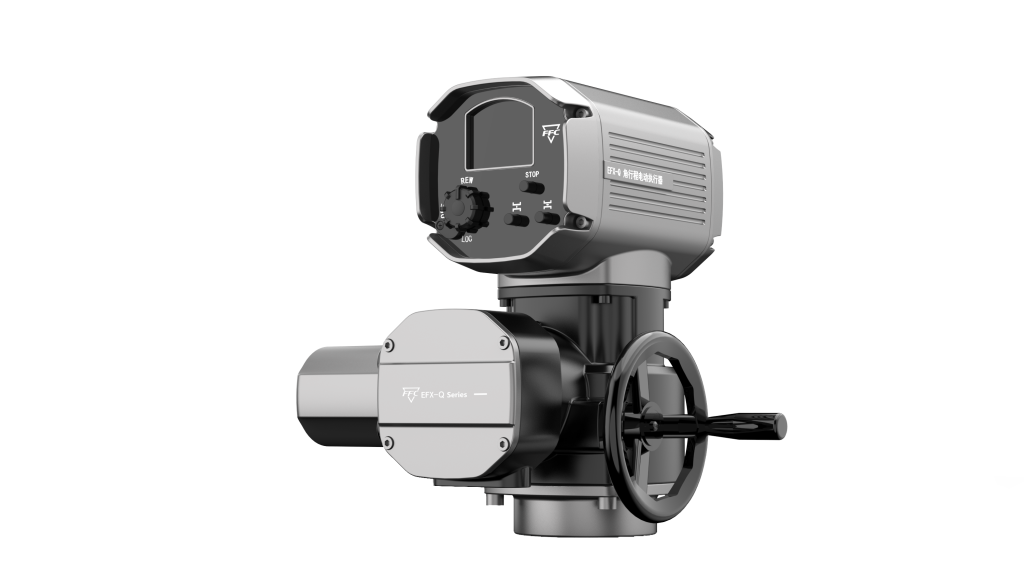

EF Quarte Turn

EF QUARTE-TURN

FFC has many years of experience in the field of fluid control. According to the different needs of the market, we have developed several series of angular stroke products. Its reliable and stable performance has a good reputation in the field of valve fluid control.

Series Feature

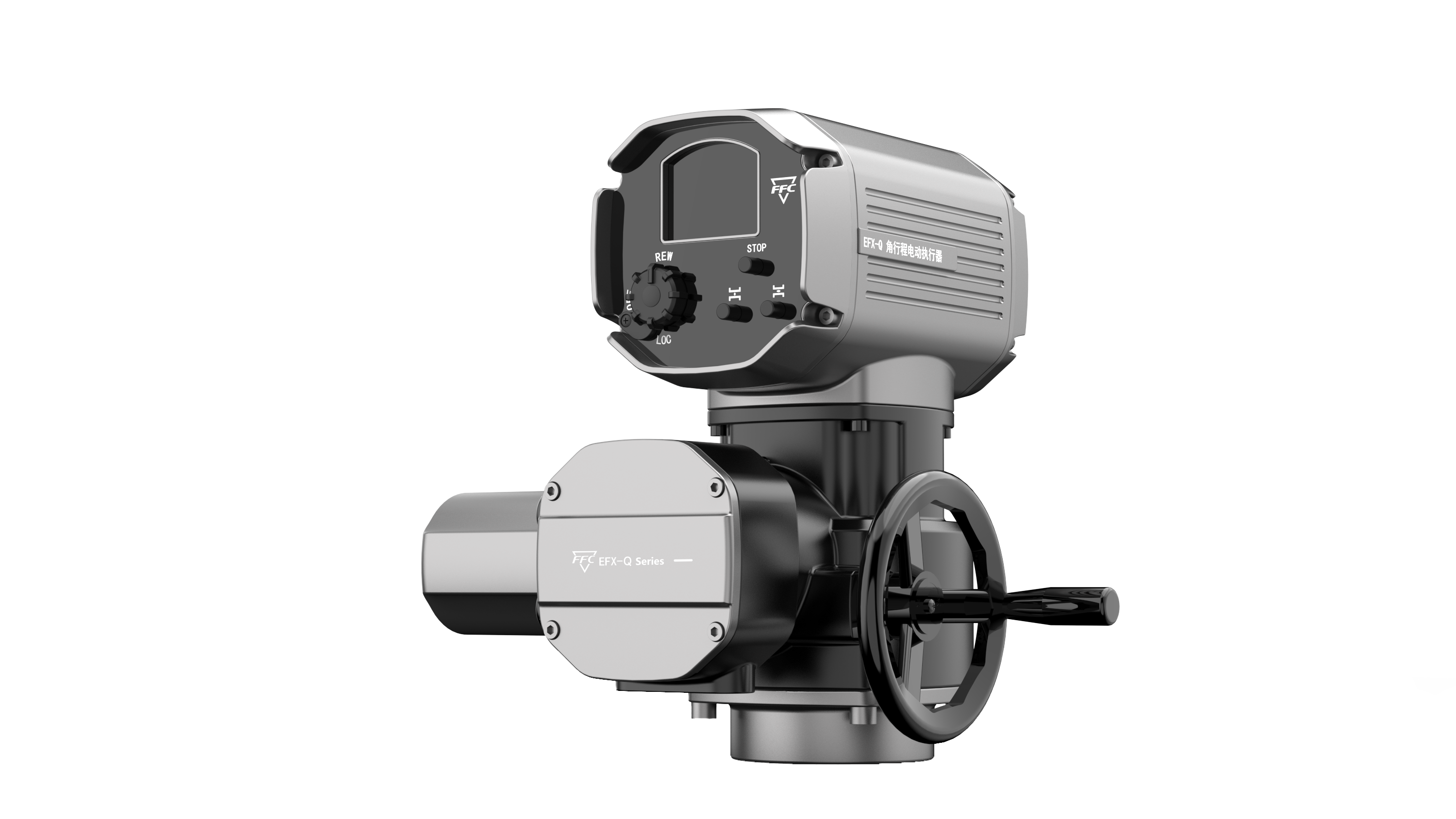

Manual operation

EF-Q/EFX-Q series angle stroke electric actuators are equipped with manual/electric automatic switching function. The clutchless design allows the handwheel to be rotated even when the product is running electrically, without interfering with each other, thus ensuring the safety of the operator. This design mechanism will become the mainstream trend of the industry in the future.

Infrared remote control

Intelligent actuators can be supplied with different remote control setters for different applications, including portable infrared remote controls for general locations.

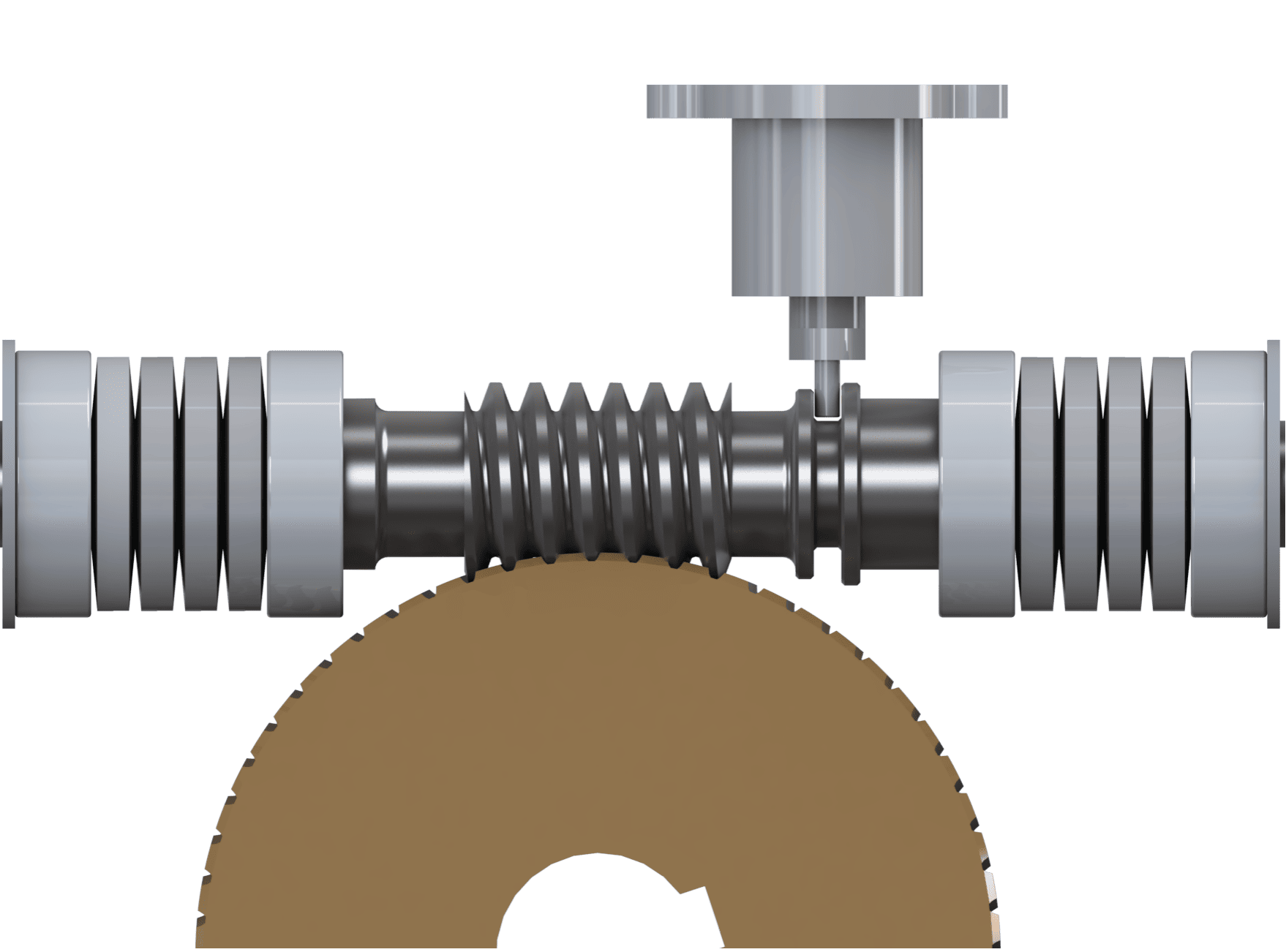

Output torque control

Output torque control: Mechanical torque is the most stable torque limiting mechanism, which is not constrained by factors such as temperature, pressure and mechanical efficiency. Meanwhile, when the actuator is started, the disc spring effectively acts as a cushion, which makes it easy to start the motor.

Operational security

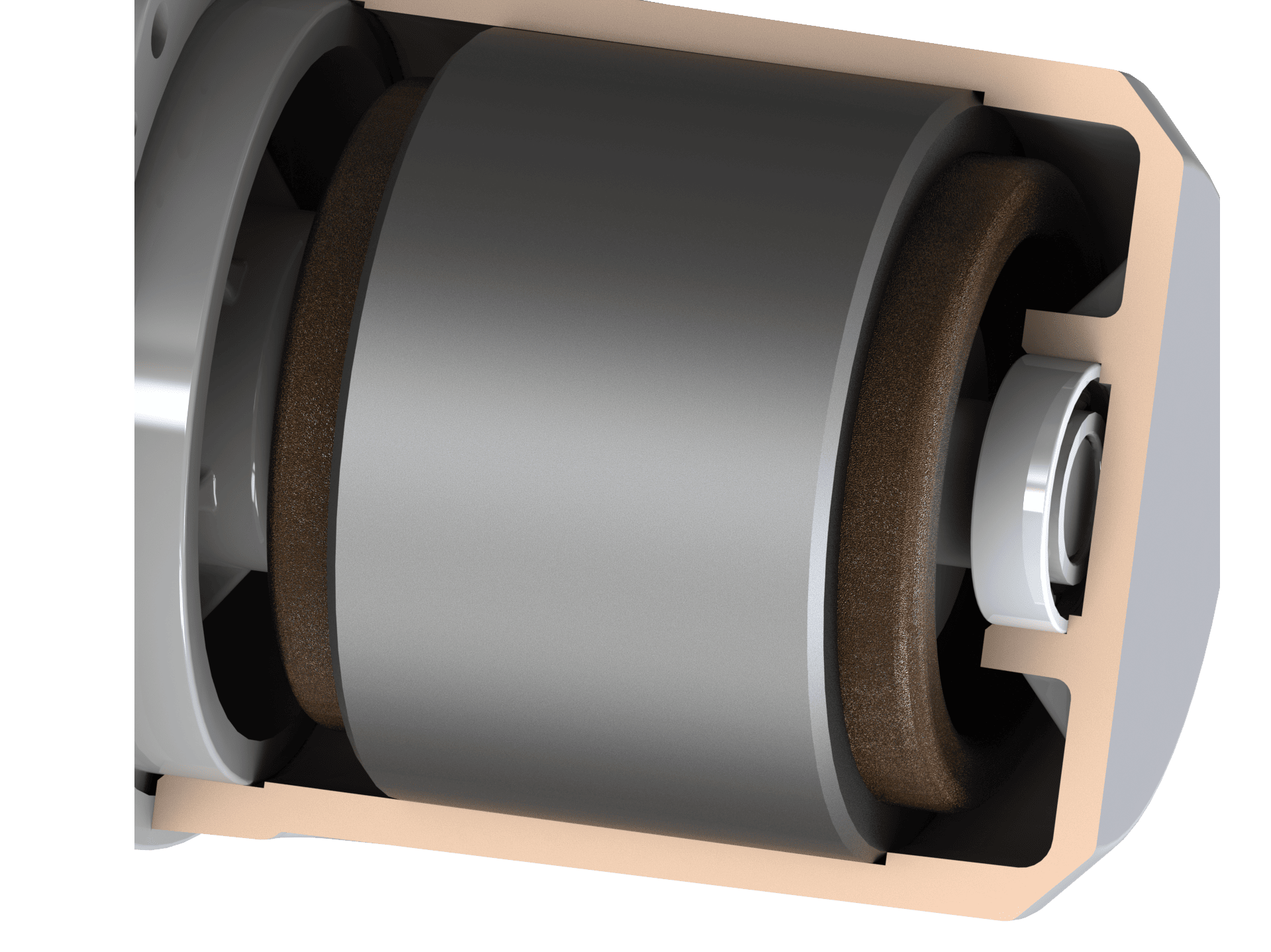

Class F insulated motor, with 2 temperature control switches at different positions of the motor winding to monitor the motor temperature, the redundant design ensures the safe operation of the motor (Class H optional).

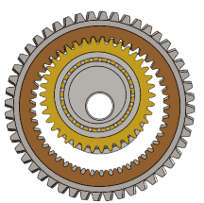

Transmission unit

Adopting high-strength alloy steel planetary gears with less gear difference, compact and efficient, realizing greater output torque in the same volume.

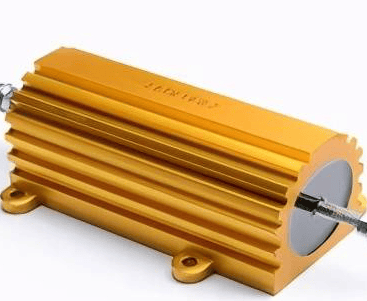

Moisture-proof heaters

Moisture-proof heating resistors are installed inside the electric actuator to remove internal condensation and prevent damage to electrical components.

Product working environment

Epoxy resin powder coating. Can be customized according to customers’ requirements.

IP67 rating with optional IP68 (7m underwater, 72 hours non-leakage)

FFC’s high-temperature fireproof cover to meet the needs of special situation use. (Can be customized according to customers’ requirements)

Exd II CT6 is designed to meet the requirements for use in hazardous locations.

Temperatures range from -20°C to 70°C, with an optional low temperature of -40°C to 55°C.

<95% (25°C)。

Request A Free Quote / Product Catalog

Components

- Lifting ring: Easy to handle and use for on-site installation and construction

- Double-sealed structure of the wiring chamber: during the actuator installation and The electric actuator is well sealed inside during the actuator installation and test.

- Up to 51 terminals, no need to install special wiring brass ring. The direct connection is possible without the need to install special wiring brass rings, which makes the field installation easier.

- The bottom connection size is ISO 5210 international standard.

Intelligent electric actuator adopts high-performance microprocessor to collect real-time operating information such as valve position, torque, etc., and carry out logic operation to truly reflect the operating status of the actuator. Provide reference for the maintenance of the actuator. Provide reference for actuator maintenance.

Time position curve

The curve shows the trend of the actuator’s operation up to now, showing the number of times the actuator has passed in the corresponding position.

Average torque curve

The average torque curve in the open and closed directions records the average output torque of the actuator in the corresponding positions in the two directions, and provides an overview of the operating load of the actuator.

Operating trend curve

The curve shows the cumulative number of positions corresponding to the control signals received by the actuator so far.

Product Life

| Load type | Load(N.m/N) | FFC product lifetime | Design standard |

| CLASSA/CLASSB | ≤700 | 15000 switches | BSEN15714-2 |

| CLASSA/CLASSB | 701-2500 | 10,000 times switching | ISO5210 |

| CLASSC | ≤700 | 1800000 starts | ISO5211 |

| CLASSC | 701-2500 | 1200000 starts | IEC 60034-1 |

| CLASSA/CLASSB | ≤2000 | 20,000 switching | ISO22153 |

| CLASSA/CLASSB | 2001-4000 | 10,000 switching | |

| CLASSA/CLASSB | 4001-32000 | 5000 times switching | |

| CLASSC | ≤1000 | 1800000 starts | |

| CLASSC | 1001-4000 | 1200000 starts | |

| CLASSC | 4001-32000 | 50,000 starts |

| Actuator Model | Load Rating | FFC rated load | Design standard |

| EF-D/EFX-D(On-Off) | CLASS A/CLASS B | 60 times/hour, S2-15Min | BSEN15714-2 |

| ISO5210 | |||

| EF-D/EFX-D(Modulating) | CLASS C | 1200 times/hour, S4-50% | ISO5211 |

| EF-Q/EFX-Q(On-Off) | CLASS A/CLASS B | 600 cycles/hour, S2-15Min | IEC 60034-1 |

| EF-Q/EFX-Q(Modulating) | CLASS C | 1200 cycles/hour, S4-50% | ISO22153 |

Contact Us For EF Quarte-turn Series Projects

Share your thoughts and customize your product.

Frequently asked questions

Switching intelligent type standard 4-20mA signal (and 0-10V, 2-10V), with LCD open degree display, do not need to be equipped with a separate control cabinet.

This item is optional

Buna-N O-ring seal: minus 30 degrees to 120 degrees, suitable for medium mineral oil, gasoline, benzene.